- Products Products

-

Solutions

Solutions

Solutions

Innovative solutions for residential and commercial projects

-

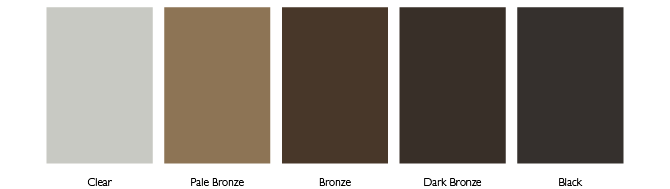

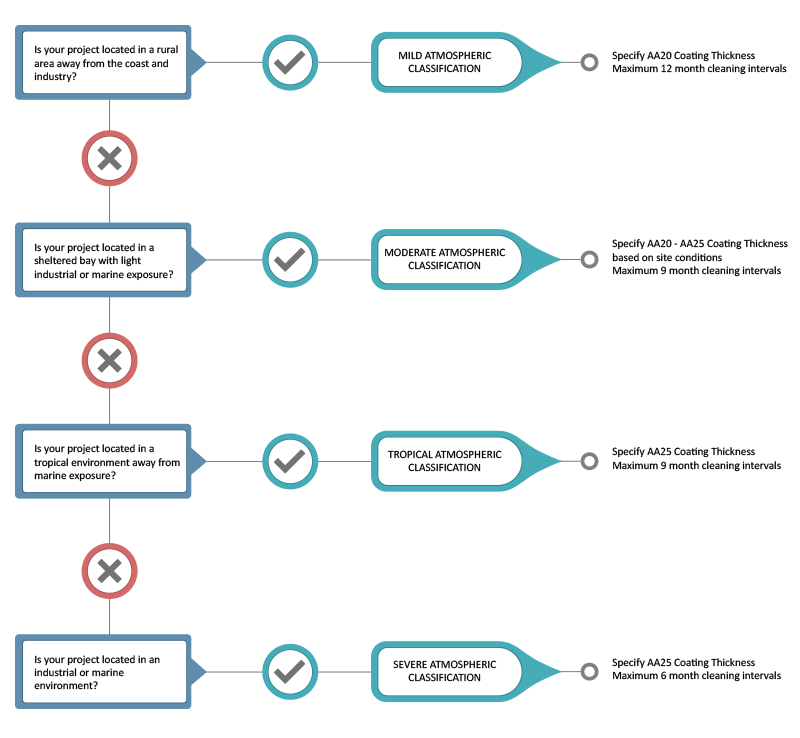

Resources

Resources

Resources

Information to help you make informed decisions

- Inspiration Inspiration

-

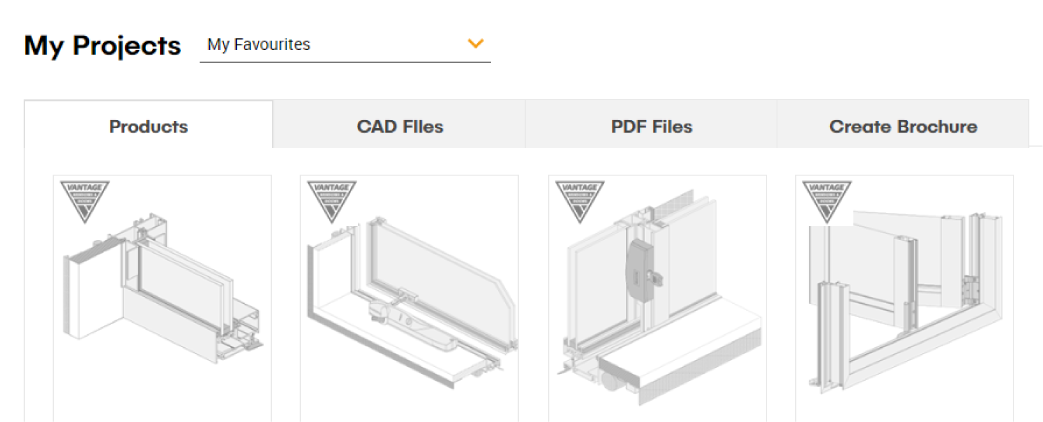

Spec Assist

Spec Assist

Spec Assist

Quick and easy access to your favourite products and resources

- Contact Contact